Material Extrusion

Material Extrusion encompasses two broad families:

Fused Filament Fabrication (FFF): Thermoplastic filament is heated and extruded through a nozzle to build parts layer by layer. This process is widely used for prototyping, tooling, and increasingly for end-use components in both desktop and large-format systems.

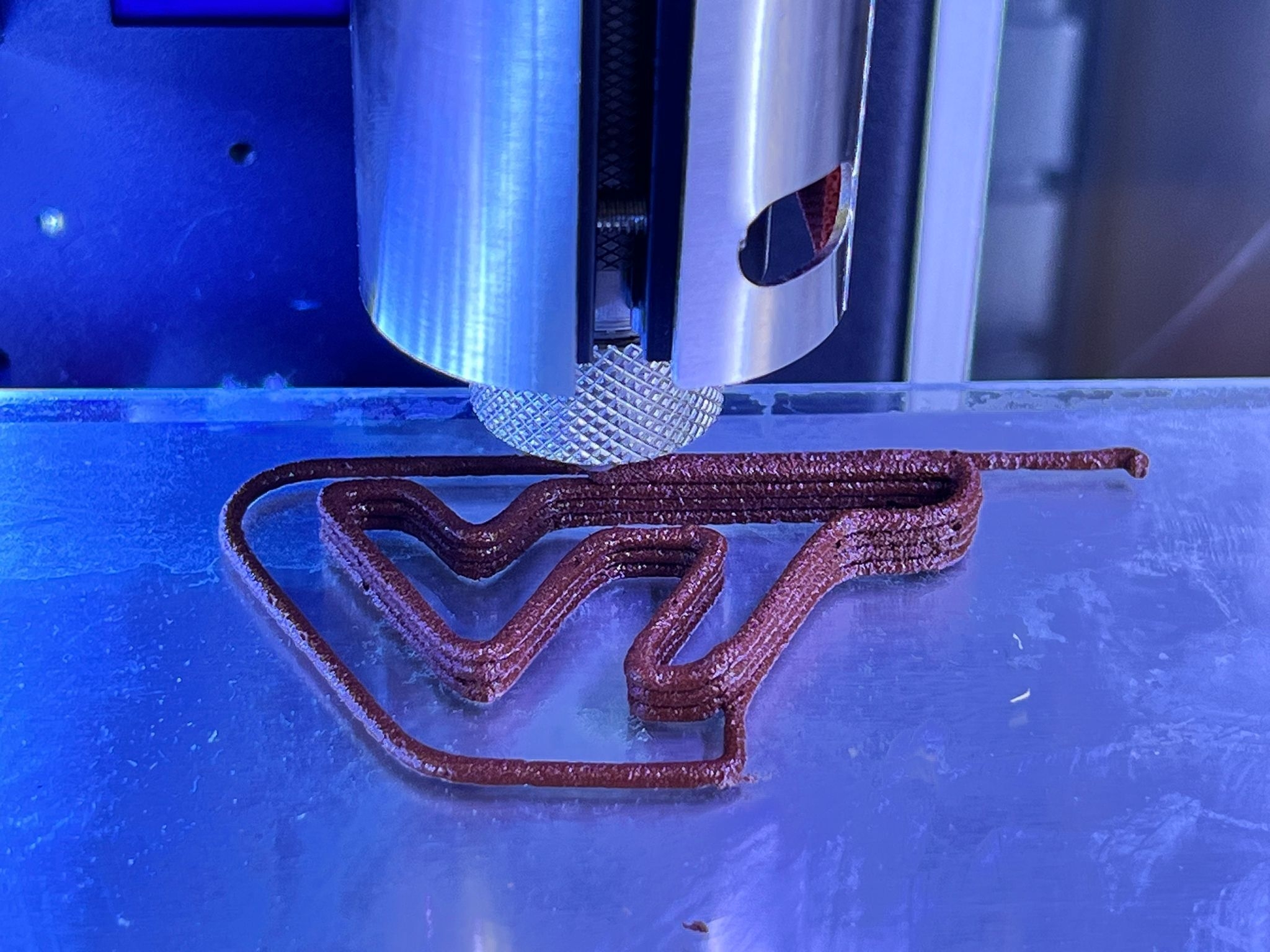

Direct Ink Write (DIW): A related extrusion process where inks, pastes, or highly filled resins (rather than filaments) are dispensed through a nozzle. Shape fidelity is maintained via rheological control and/or in-situ curing. DIW supports ceramics, metals, elastomers, and functional composites that are not processable in FFF.

DREAMS Lab has advanced multi-axis robotic FFF to overcome anisotropy by enabling non-planar toolpaths, demonstrating property improvements over conventional planar extrusion. The group has custom printers with which the effect of heated environments on print properties is being studied along with modelling to predict interlayer temperatures and their effect on parts.

In the DIW space, we systematically study the rheology, curing kinetics, and thermal behavior of our inks to ensure processability and shape retention. We link ink flow properties to print fidelity, curing response, and final part performance. Previously, extrusion of high-performance materials via UV-assisted DIW has been studied, including all-aromatic polyimides that retain properties at elevated temperatures. The lab has also hybridized DIW with mask-projection VPP to process ultra-high-viscosity resins. Current projects focus on highly filled material extrusion of ceramic composites, low melting alloys for printing conductive traces and Functionally graded structures.