Metal Powder Bed Fusion

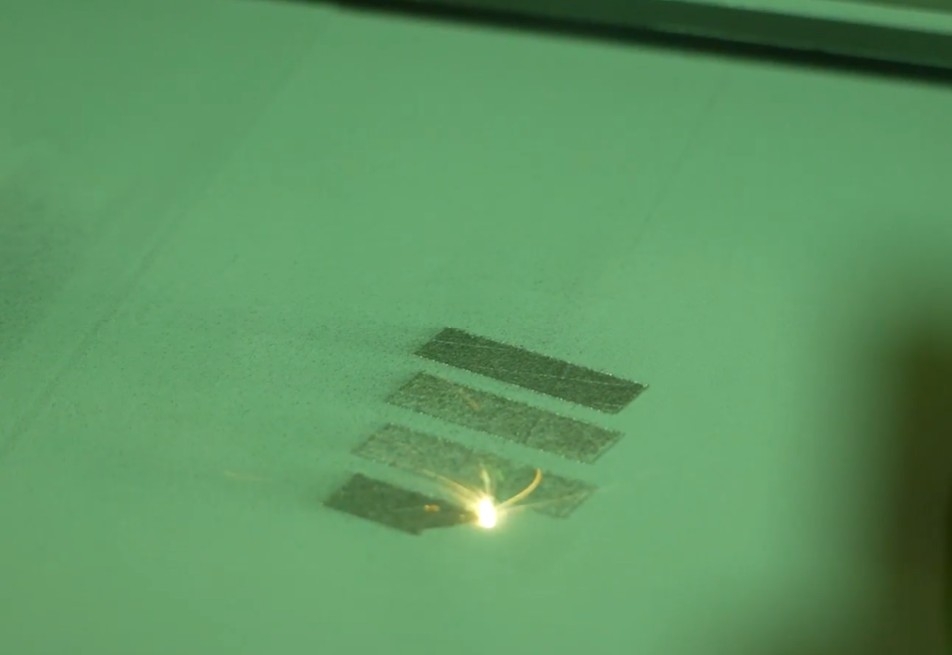

Metal Powder Bed Fusion (PBF) uses a laser or electron beam to selectively fuse layers of metal powder, producing dense and complex components with excellent mechanical performance. PBF has been widely adopted in aerospace, biomedical, and tooling industries due to its ability to fabricate lightweight structures and high-performance alloys.

In the DREAMS Lab, our contributions to metal PBF emphasize design for additive manufacturing (DfAM) and process-structure-property relationships. We investigate how geometry, thermal histories, and build orientation affect microstructure. We develop new models to predict the effects of the thermal history on microstructure, and hence on the part properties.