Material Jetting

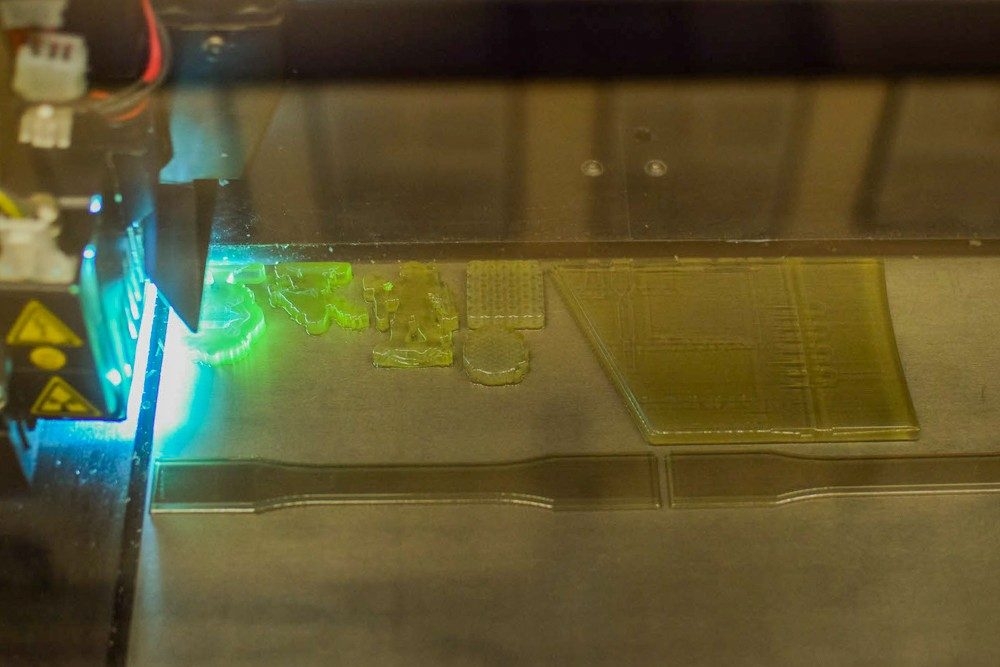

Material jetting is similar to inkjet document printing, but instead of jetting drops of ink onto paper, PolyJet 3D printers jet drops of liquid photopolymer onto the build tray. Multiple print heads jet material simultaneously to create each layer, and UV light is then used to cure the layers. These layers build up one at a time in an additive process to create a 3D model. Fully cured models can be handled and used immediately without additional post-curing. Along with the selected model materials, a gel-like support material facilitates successful printing of complicated geometries. Support material can be removed by hand or by a high-powered water jet station.

Our research at the DREAMS Lab has characterized mechanical variability and anisotropy in PolyJet materials, showing how build orientation and part aging affect performance. These findings are critical for validating Material Jetting in engineering applications. Beyond characterization, we have applied MJ to biomedical constructs and embedded RF/electronic structures, leveraging its precision and material-mixing capabilities to explore new functional domains. Current projects also involve predicting the jettability of high viscosity materials using modelling techniques.